Metal Fabrication Coffs Harbour

Serving from South West Rocks to Yamba and everywhere in between.

Your Local Experts

Watsons Aluminium is the fabricator in Coffs Harbour that provides precise craftsmanship and quality results. With state-of-the-art equipment at our disposal, we ensure every cut, fold and weld meets the highest standards.

For

general aluminium and stainless steel solutions, trust in our expertise. We also sell extrusions and offer sheet cut to size. Call us today on

(02) 6652 6566 for a free quote. From South West Rocks to Yamba, our family owned and operated business has got you covered.

Crafting metal to meet your specific needs, we bring visions to life with general fabrication. Our skilled team ensures quality products for various applications.

Elevate the look of your outdoor space with our aluminium picket-style fences and balustrades. Ideal for patios, terraces and more.

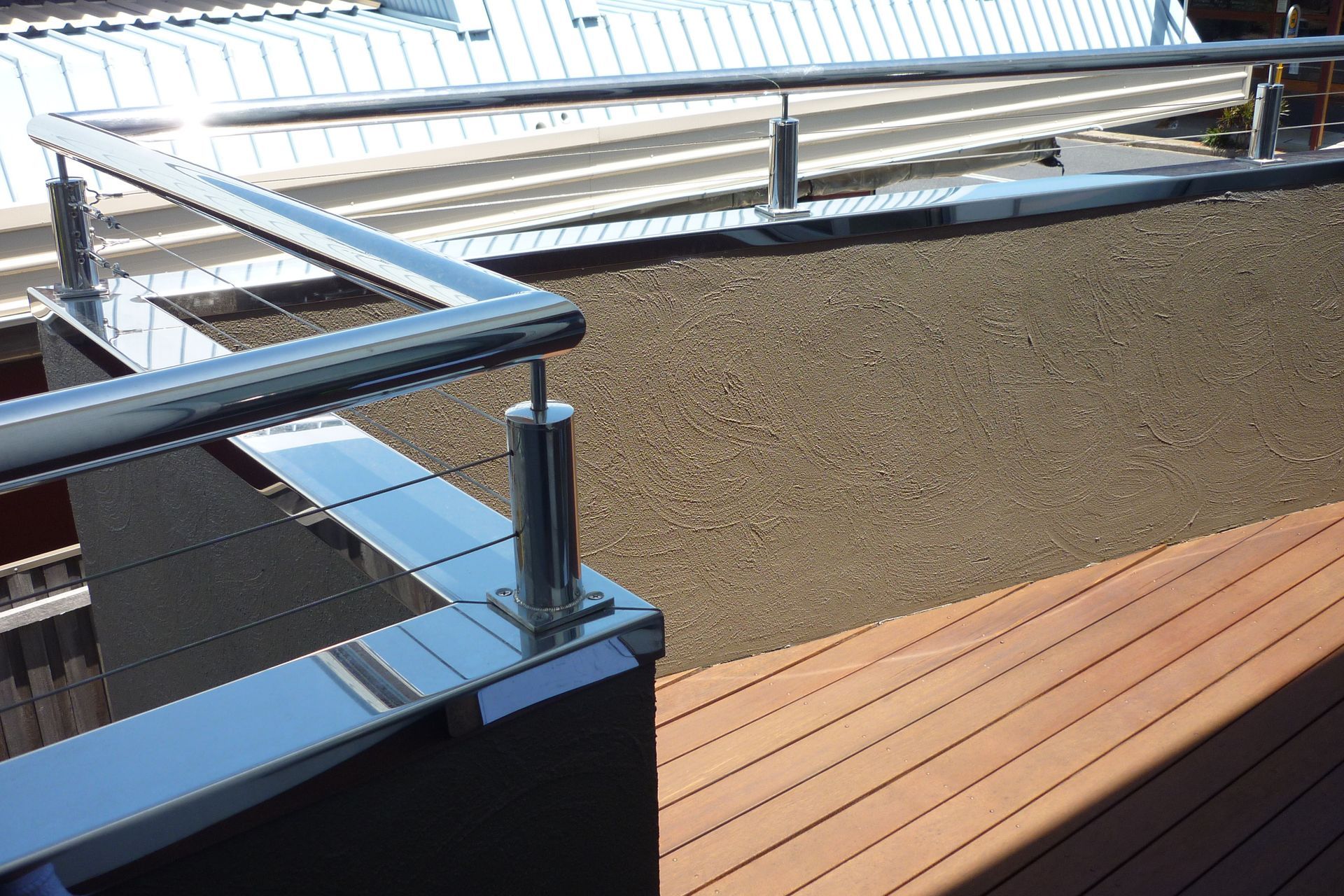

Choose stainless steel for its gleaming beauty and tough nature. It's the metal that offers both style and substance for any project.

Define your space with glass and aluminium balustrades that blend security with style. Our range offers a perfect match for your architectural vision.

Safety meets design with our handrails and grab rails. We ensure secure, stylish and sturdy handrails for any staircase or balcony.

Elevate your pool area with our frameless fencing options, combining safety and unobstructed views to stunning effect.

We design, fabricate and install automatic gates using high-quality aluminium and stainless steel. Our solutions are convenient and secure.

Our slatted gates and fences are the epitome of security and sophistication. Count on us to deliver stylish, secure solutions for your home or business.

About Aluminium Products

Aluminium stands as a marvel in the metal fabrication industry. We harness its remarkable attributes to deliver products that stand the test of time. Our use of aluminium translates into creations that are enduring and lightweight while also embodying elegance and versatility.

Trust in aluminium for a future proof investment. Benefits of aluminium include:

- Low maintenance

- Durable

- Lightweight

- Affordable

- Easily fabricated

About Stainless Steel

The integrity of stainless steel is unmatched. Its resistance to corrosion and enduring strength make it a cornerstone in metal fabrication. We craft each piece with a vision of longevity, ensuring the stainless steel's natural lustre and robustness enhance the spaces it occupies.

Some benefits of stainless steel include:

- Strength

- Prestige

- Rust resistant

- Heat resistant

- Modern, bright appearance

Precision Aluminium Solutions for Every Project

Expert Metal Fabrication in Coffs Harbour

Who We Are

At Watsons Aluminium, we pride ourselves on delivering exceptional metalwork to Mid North Coast communities, from South West Rocks to Yamba. We blend over a century of combined expertise with a deep commitment to bespoke service and quality.

Each project is a testament to our dedication to your satisfaction. Whether cutting, rolling, welding or folding, our skilled team and premium machinery can tackle any project.

Call (02) 6652 6566 to get started with metal fabrication in Coffs Harbour.

Why Choose Our Metal Fabrication Services?

Choosing us means choosing a trusted name in metal fabrication in Coffs Harbour. As a family-owned and operated business, we take great pride in our reputation for reliable service, premium craftsmanship, and personalised customer care. Our fabricators bring years of hands-on experience and technical knowledge to every project, ensuring results that not only meet but exceed expectations.

We offer a seamless process from consultation through to installation, keeping you informed at every step. With our fully equipped workshop and experienced team, we’re able to fabricate custom solutions that meet your project’s specifications, timeline, and budget. Our dedication to quality, paired with our focus on practical design and local knowledge, makes us the first choice for those seeking trusted metal fabrication in the Coffs Harbour area.

Contact Watsons Aluminium Today

Are you ready to get in touch with the top company for metal fabrication in the area? Reach out to our experienced and reliable team at Watsons Aluminium today. We are skilled in stainless steel, glass and aluminium fabrication.